torsion springs

Explore our range of premium custom torsion springs designed and manufactured in Logansport, IN. At Myers Spring, we prioritize precision and quality in every product.

The Myers Spring Advantage

Get precision-engineered torsion springs designed to meet all your needs. As your trusted torsion spring manufacturer in Logansport, IN, Myers Spring takes pride in crafting high-quality torsion springs.

High stress and corrosion can drastically decrease the life of a torsion spring. We offer designs, materials and processes to improve fatigue life. We also have many exceptional materials and coatings for better corrosion resistance.

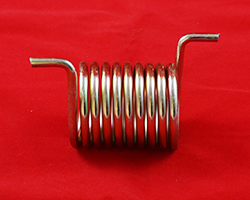

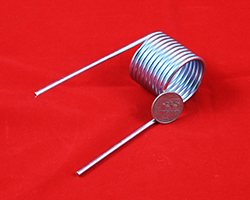

Available in wire diameters from .005” to 1.000,” round and square wire.

With Myers Spring, you get high-quality craftsmanship and dependable solutions. Contact us today to see how our torsion springs can enhance your projects!

How Our Torsion Springs Work

Our torsion springs are geared to deliver powerful rotational force precisely when and where you need it. Torsion springs resist or exert a rotational force or torque. Unlike compression springs, torsion springs twist along their axis, decreasing in diameter and increasing in length as force is applied. Myers Spring’s torsion springs are carefully crafted for exceptional outcomes. As leading heavy-duty torsion spring suppliers, we custom-engineer our springs to fit your needs perfectly. Being a Lean Manufacturer is our commitment to you. We deliver superior quality parts at the lowest total price by eliminating waste and reducing costs daily. Our team achieves this through faster changeovers, level-loading machines, and 100% ERP utilization. Trust Myers Spring for expertly crafted torsion springs and experience unparalleled quality and performance. Contact us today!

The Types of Torsion Springs We Offer

We offer both single and double custom torsion springs in wire diameters ranging from 0.005" to 1.000" full hard and 1.200" annealed. Our springs come with various end configurations to meet your needs.

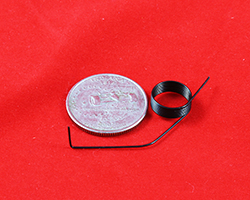

Single Torsion Springs

Our single torsion springs are cost-effective and perfect for applications requiring rotational force in one direction.

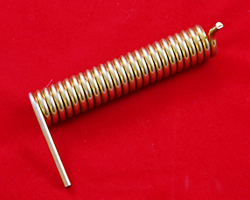

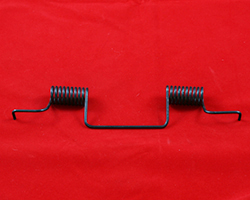

Double Torsion Springs

Myers Springs’ double torsion springs feature two coiled sections, one right-hand wound, and one left-hand wound, connected. Offering enhanced stability and a broader range of motion, they’re commonly used for applications needing bidirectional force.

FAQs

What are torsion springs used for?

Torsion springs are typically used in applications requiring rotational force. Common examples include clothespins, old-fashioned clocks, and similar devices.

How do torsion springs work?

When torsion springs twist along their axis, they store energy, which is then released as rotational force or torque to ensure smooth and controlled motion.

What materials are used to manufacture torsion springs?

We use top-quality materials like steel, brass, bronze, titanium, and specialty alloys to make our torsion springs durable and high-performing.

How do you measure a torsion spring?

For torsion springs, measure the wire diameter, external diameter, coil length, and leg length. Accurate measurements make sure your torsion spring fits and functions flawlessly.

What is the lifespan of a torsion spring?

The lifespan of a torsion spring depends on its material, application, and usage frequency. That said, you can make them last a long time with proper maintenance.